SHURE STAR Delivers

Look to SHURE STAR for the best in specialty doors, controls, pedestrian safety products, and complete custom design solutions.

Over 100 Years of SHURE STAR Innovation

At SHURE STAR, our experienced team has exceptional engineering and manufacturing capabilities honed from 100+ years of success.Our continuity and carryover of employees, designs, and resources are key to our success. Many of our current employees have been in this business for 25 years or more and our location provides access to some of the best talent and supplier resources available.

SHURE STAR is committed to producing quality products produced to our customer’s complete satisfaction. We help our customers by providing solutions to any challenges they may have with the goal of building business relationships for years to come.

SHURE STAR Historical Highlights

SHURE STAR timeline showcases some of our many historical accomplishments.

Take a visual tour of our history, from when we began as the R. V. Harty Co., to Door-Man Manufacturing, to SHURE STAR today.

Take a visual tour of our history, from when we began as the R. V. Harty Co., to Door-Man Manufacturing, to SHURE STAR today.

Take a visual tour of our history, from when we began as the R. V. Harty Co., to Door-Man Manufacturing, to SHURE STAR today.

Four Fold Opened the Door

In 1918, R. V. Harty Co. began its journey by designing and manufacturing wooden doors in industrial and commercial applications. Four Folding, Swinging, Sliding, and Canopy Doors were hand crafted for each application.

In 1918, R. V. Harty Co. began its journey by designing and manufacturing wooden doors in industrial and commercial applications. Four Folding, Swinging, Sliding, and Canopy Doors were hand crafted for each application.

In 1918, R. V. Harty Co. began its journey by designing and manufacturing wooden doors in industrial and commercial applications. Four Folding, Swinging, Sliding, and Canopy Doors were hand crafted for each application.

Swinging into the Swing Age

In the 1920's R. V. Harty Co. based in Detroit, Michigan, began supplying the early automotive manufacturing plants with power operated doors and many custom doors for special applications.

In the 1920's R. V. Harty Co. based in Detroit, Michigan, began supplying the early automotive manufacturing plants with power operated doors and many custom doors for special applications.

In the 1920's R. V. Harty Co. based in Detroit, Michigan, began supplying the early automotive manufacturing plants with power operated doors and many custom doors for special applications.

Supplying The Wartime Economy

In 1944, R. V. Harty Co. supplied industrial facilities with Sliding and Vertical Lifting Doors for manufacturing plus hanger doors for the wartime aviation industry.

In 1944, R. V. Harty Co. supplied industrial facilities with Sliding and Vertical Lifting Doors for manufacturing plus hanger doors for the wartime aviation industry.

In 1944, R. V. Harty Co. supplied industrial facilities with Sliding and Vertical Lifting Doors for manufacturing plus hanger doors for the wartime aviation industry.

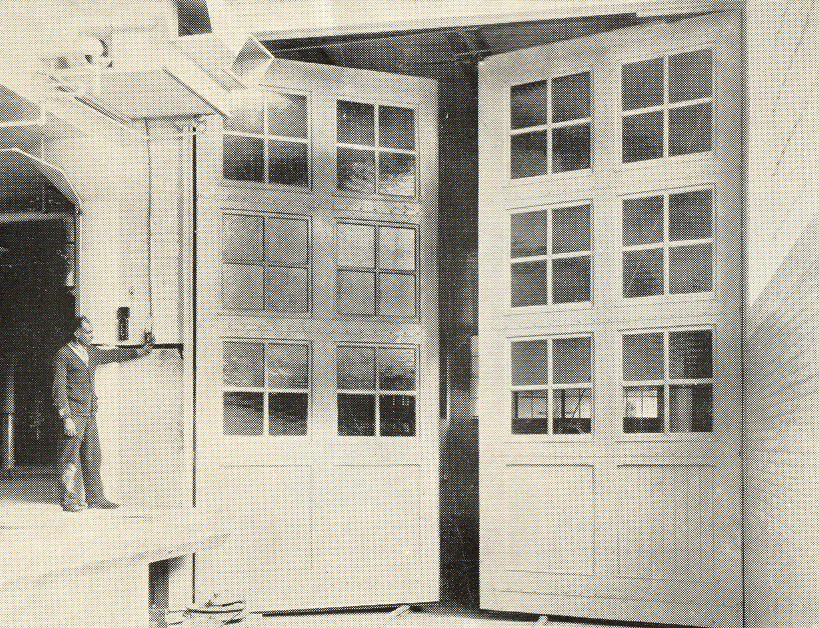

Diving Deeply into Radiation Shielding

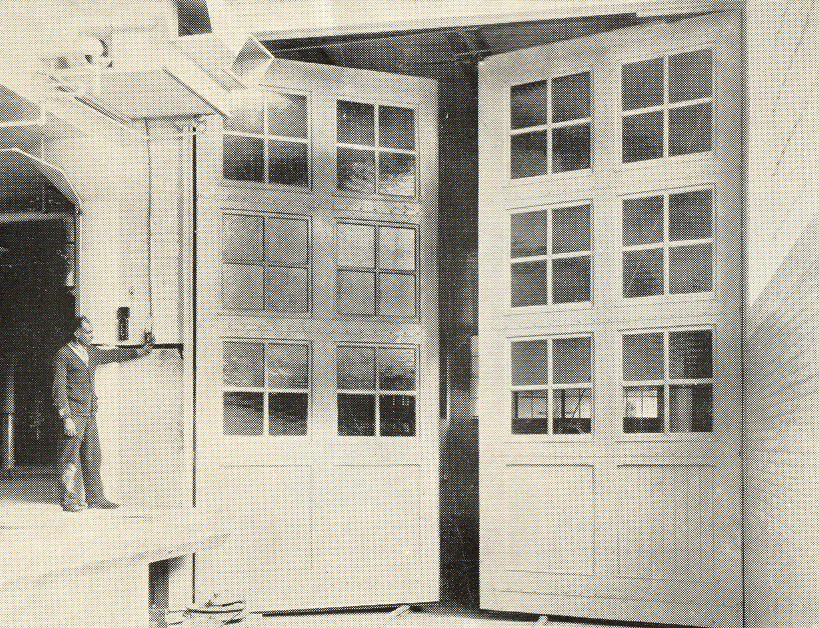

In the 1950's R. V. Harty Co. dove deeply into radiation shielding with the addition of Shielding Windows and Door Assemblies for multiple US Government facilities, including Argonne and Sandia Laboratories. These special applications included doors up to 3' thick and viewing windows with multiple layers of leaded glass reaching 6' thick.

In the 1950's R. V. Harty Co. dove deeply into radiation shielding with the addition of Shielding Windows and Door Assemblies for multiple US Government facilities, including Argonne and Sandia Laboratories. These special applications included doors up to 3' thick and viewing windows with multiple layers of leaded glass reaching 6' thick.

In the 1950's R. V. Harty Co. dove deeply into radiation shielding with the addition of Shielding Windows and Door Assemblies for multiple US Government facilities, including Argonne and Sandia Laboratories. These special applications included doors up to 3' thick and viewing windows with multiple layers of leaded glass reaching 6' thick.

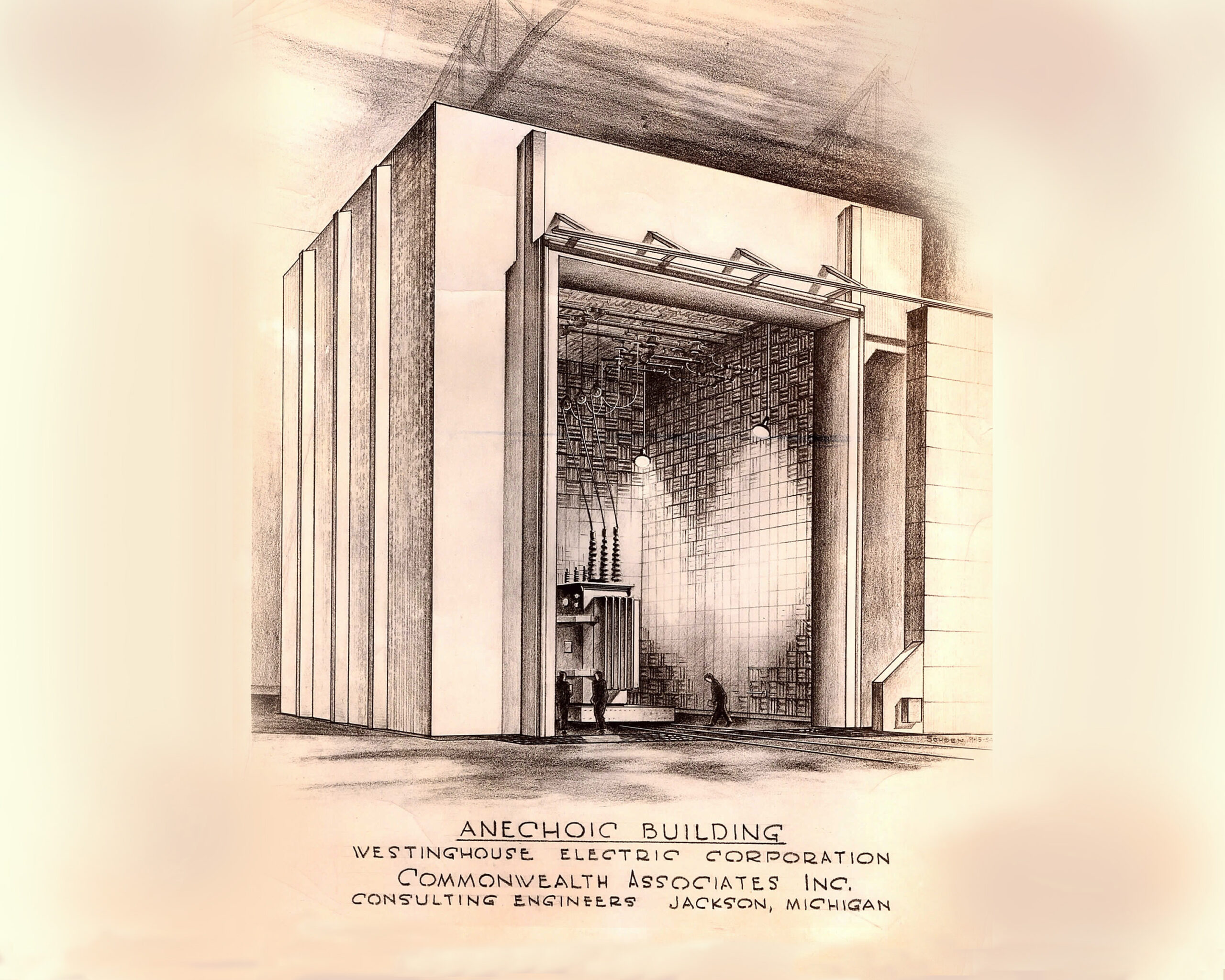

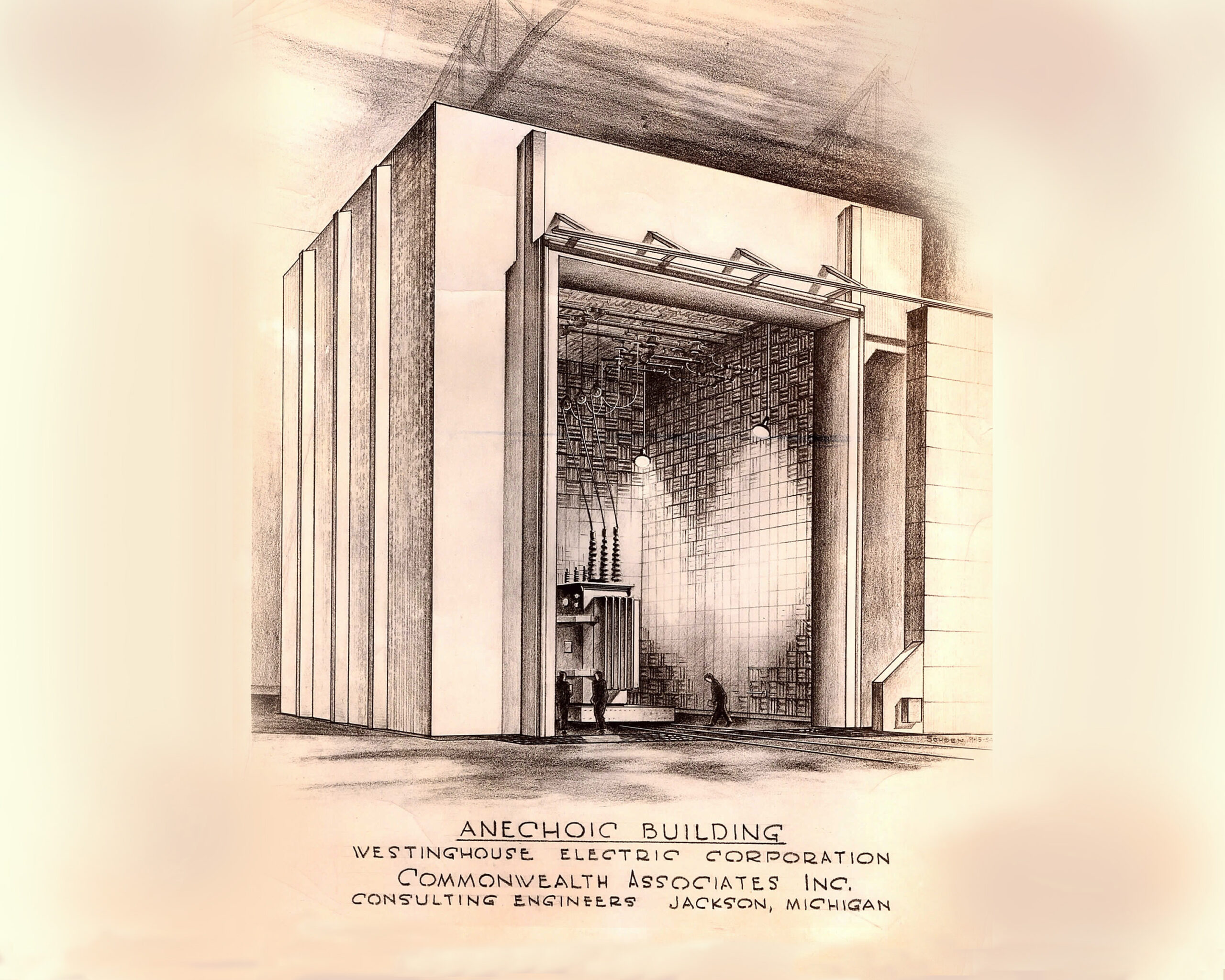

One in a Million

In 1954, R. V. Harty Co. designed and built an Anechoic Chamber Door weighing in excess of 1,000,000 pounds for Westinghouse Electric Co. in Sharon, PA.

In 1954, R. V. Harty Co. designed and built an Anechoic Chamber Door weighing in excess of 1,000,000 pounds for Westinghouse Electric Co. in Sharon, PA.

In 1954, R. V. Harty Co. designed and built an Anechoic Chamber Door weighing in excess of 1,000,000 pounds for Westinghouse Electric Co. in Sharon, PA.

Bridging the Past to the Future

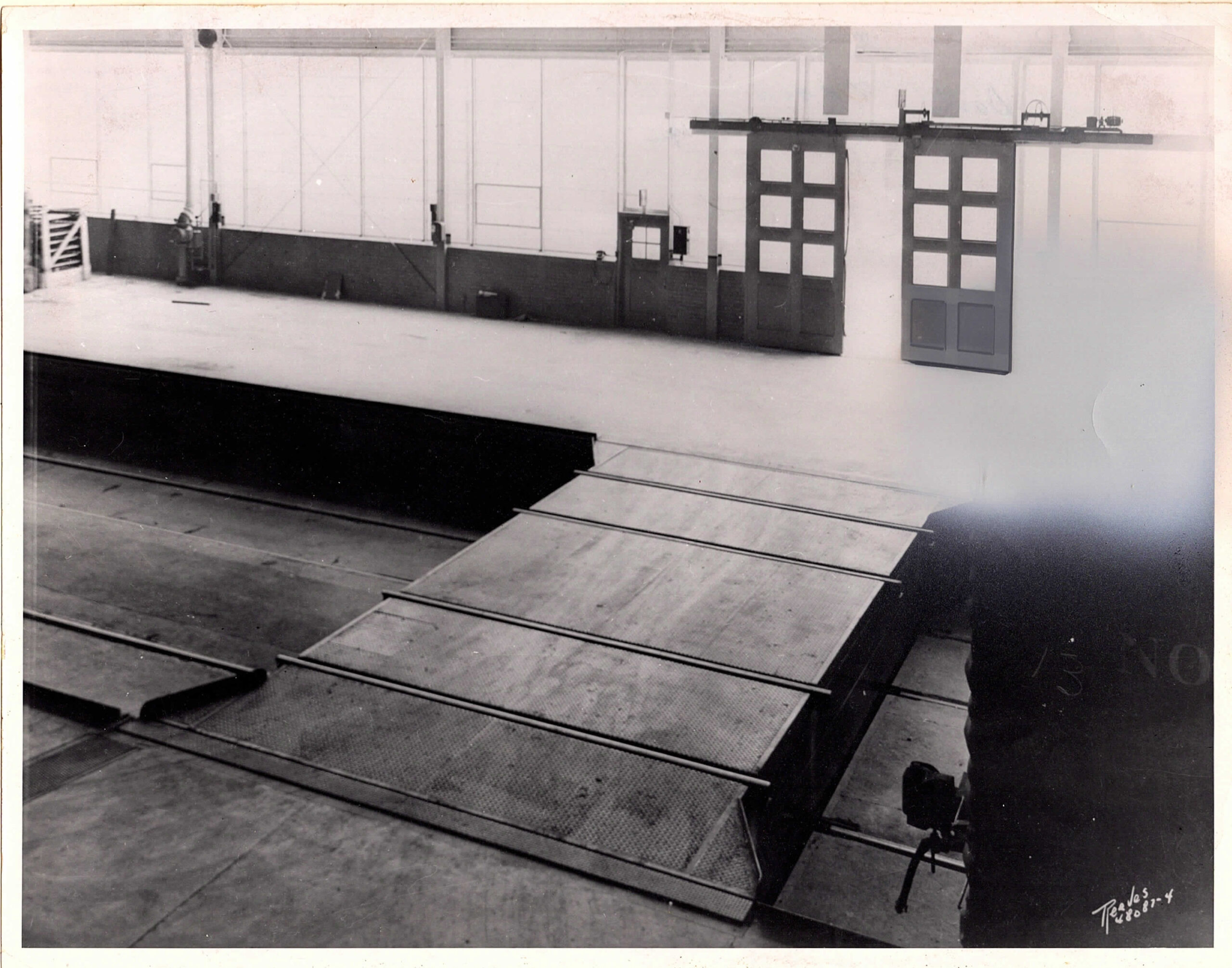

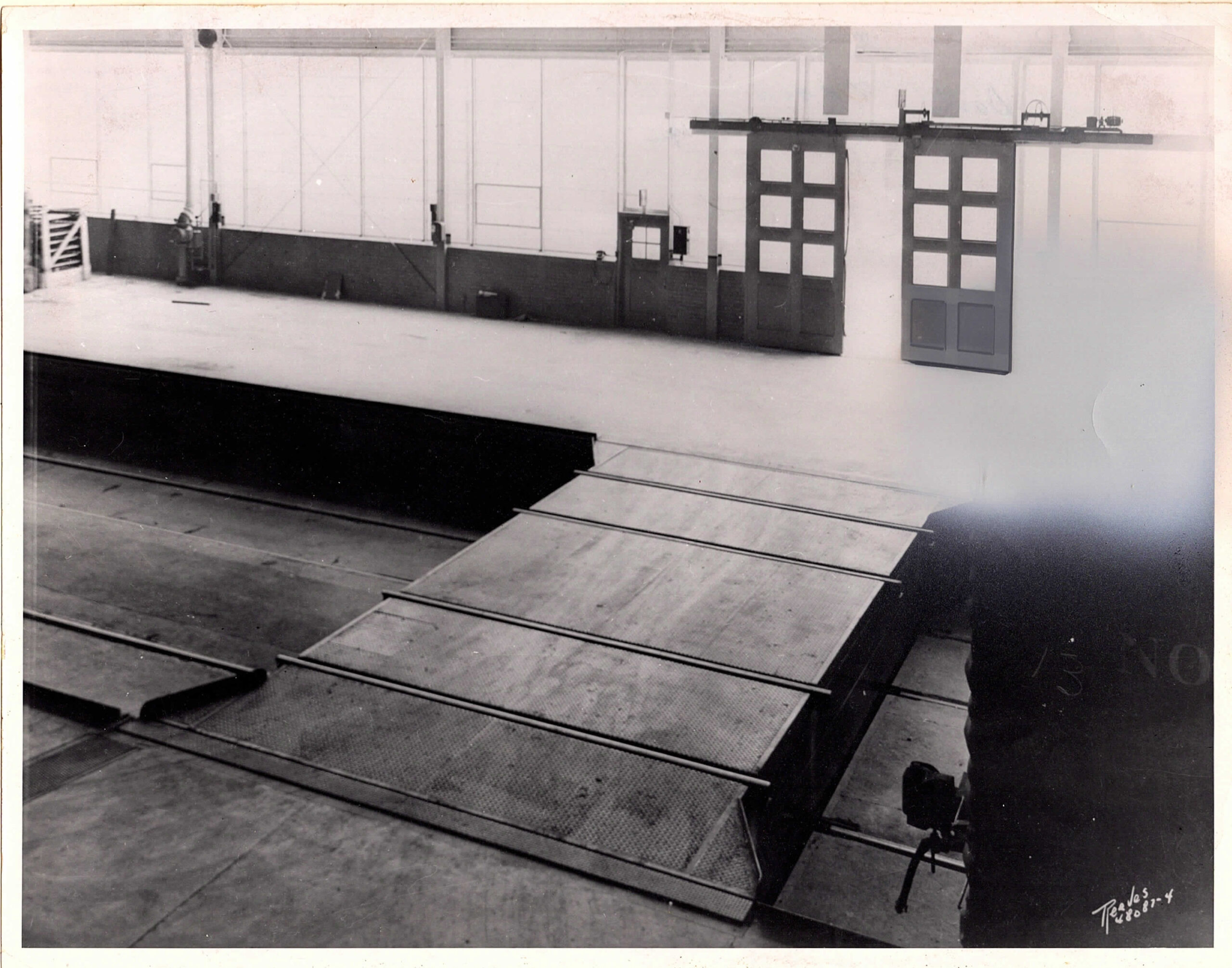

In 1959, R. V. Harty Co. patented our Vertical Lifting Bridge design. In the lower position, it allows the train to pass over the bridge which has been lowered into the floor.

In 1959, R. V. Harty Co. patented our Vertical Lifting Bridge design. In the lower position, it allows the train to pass over the bridge which has been lowered into the floor.

In 1959, R. V. Harty Co. patented our Vertical Lifting Bridge design. In the lower position, it allows the train to pass over the bridge which has been lowered into the floor.

Blasting into the Modern Age

In 1963, Door-Man Manufacturing acquired R. V. Harty Co. and embarked on ground breaking projects for NASA and overseas with Vertical Lift, Vertical Drop, Nuclear, Blast, and Radiation Shielding Doors ready for the space age.

In 1963, Door-Man Manufacturing acquired R. V. Harty Co. and embarked on ground breaking projects for NASA and overseas with Vertical Lift, Vertical Drop, Nuclear, Blast, and Radiation Shielding Doors ready for the space age.

In 1963, Door-Man Manufacturing acquired R. V. Harty Co. and embarked on ground breaking projects for NASA and overseas with Vertical Lift, Vertical Drop, Nuclear, Blast, and Radiation Shielding Doors ready for the space age.

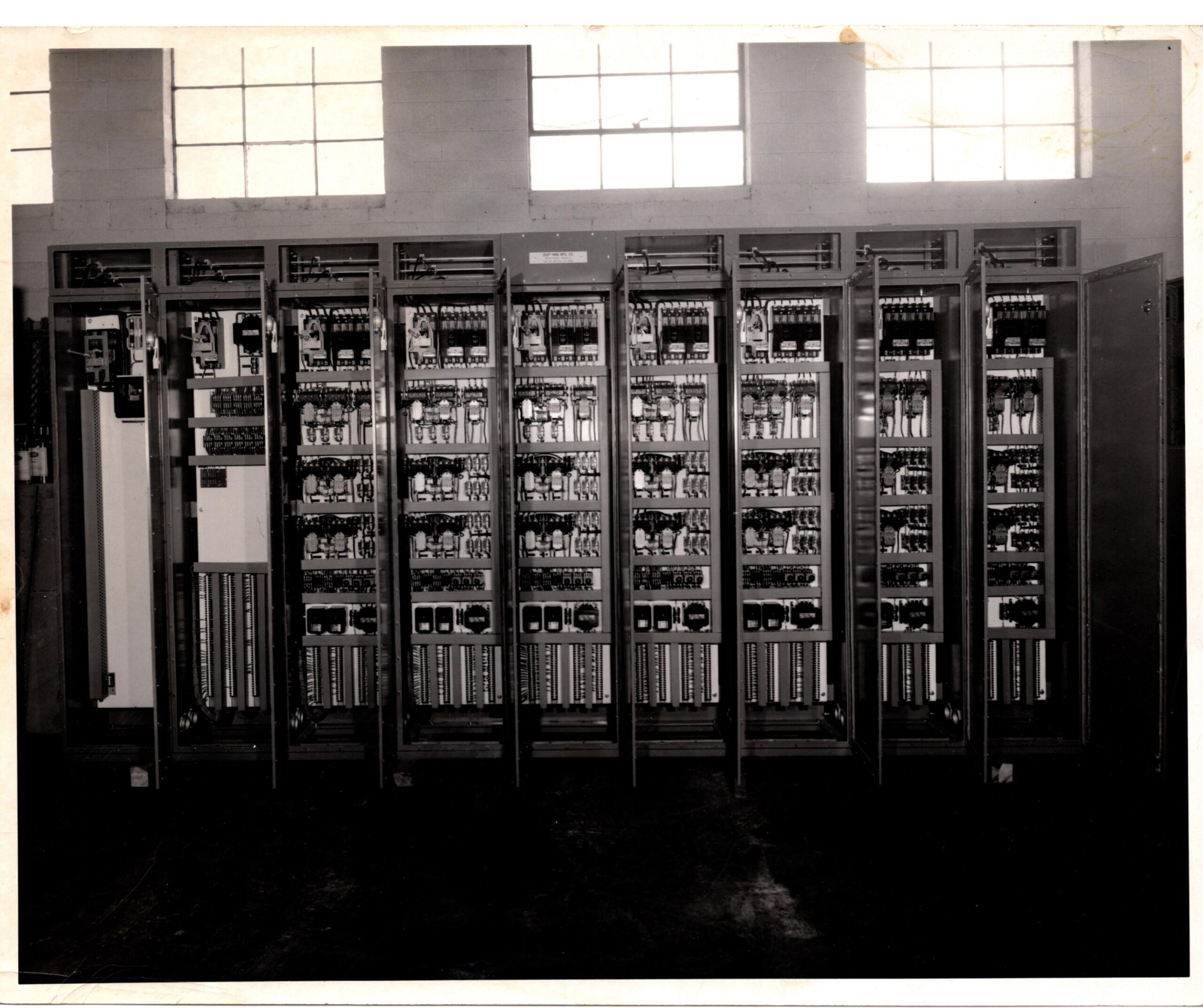

Mastering the Art of Control

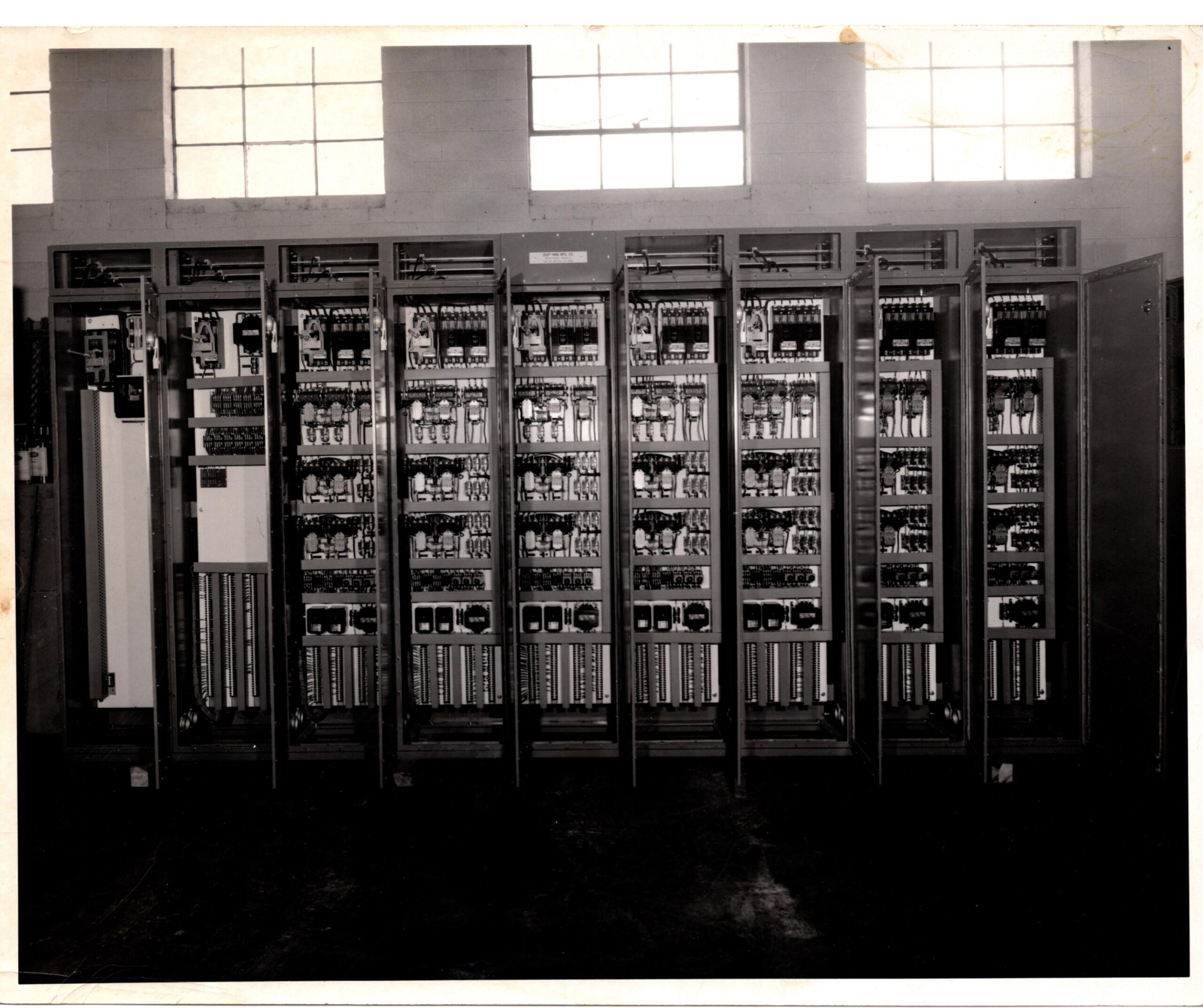

This motor control center is for one of the four 55' x 315' Vertical Lifting Doors for the Vertical Assembly Building at NASA, which are the largest Vertical Lifting Doors in the world. Designed, tested and installed by Door-Man Manufacturing.

This motor control center is for one of the four 55' x 315' Vertical Lifting Doors for the Vertical Assembly Building at NASA, which are the largest Vertical Lifting Doors in the world. Designed, tested and installed by Door-Man Manufacturing.

This motor control center is for one of the four 55' x 315' Vertical Lifting Doors for the Vertical Assembly Building at NASA, which are the largest Vertical Lifting Doors in the world. Designed, tested and installed by Door-Man Manufacturing.

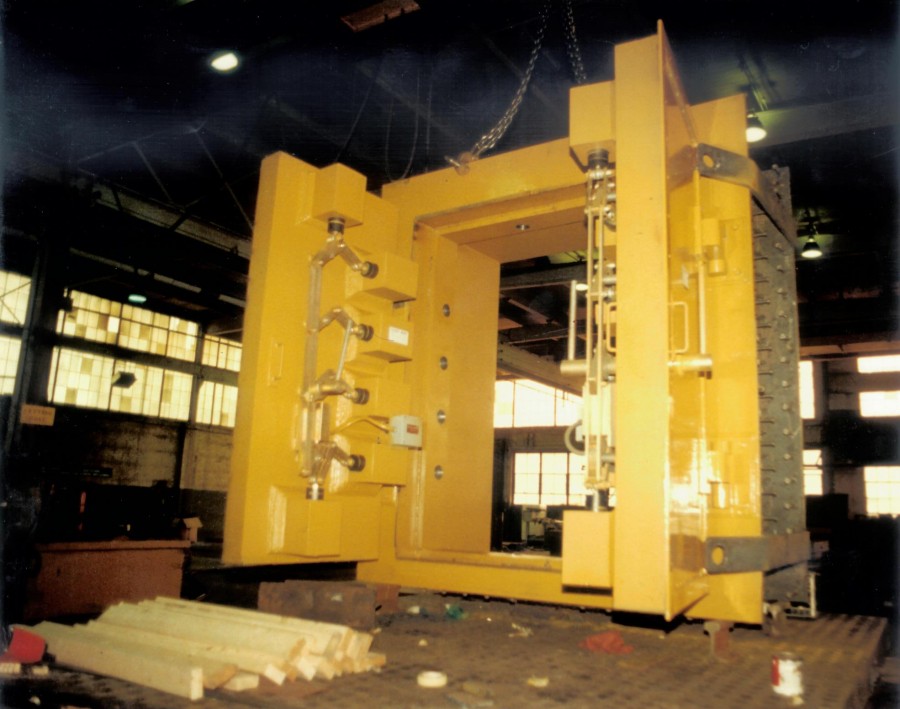

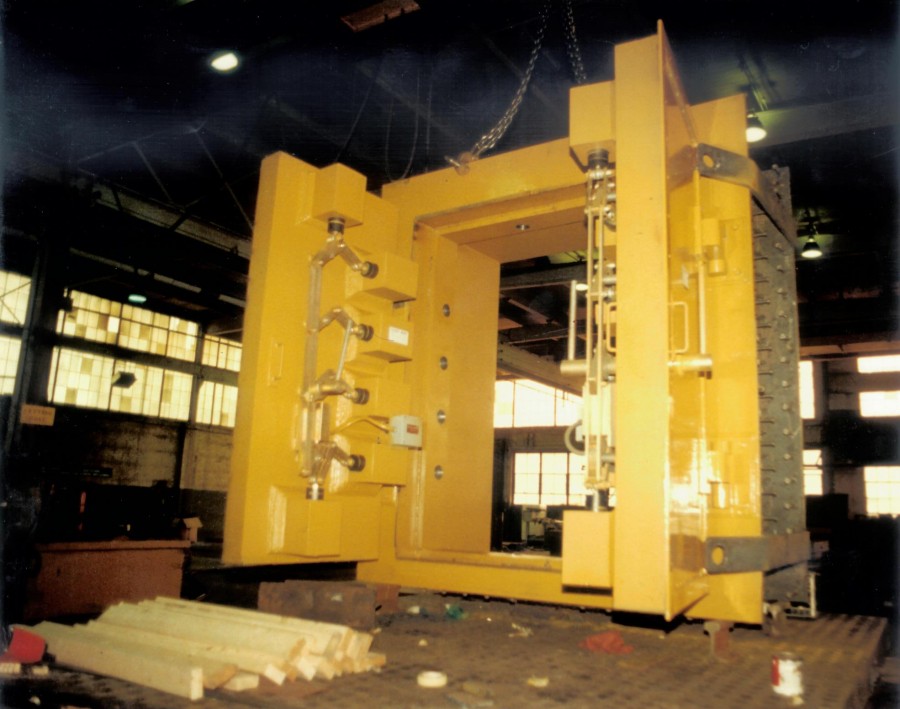

Performance Under Pressure

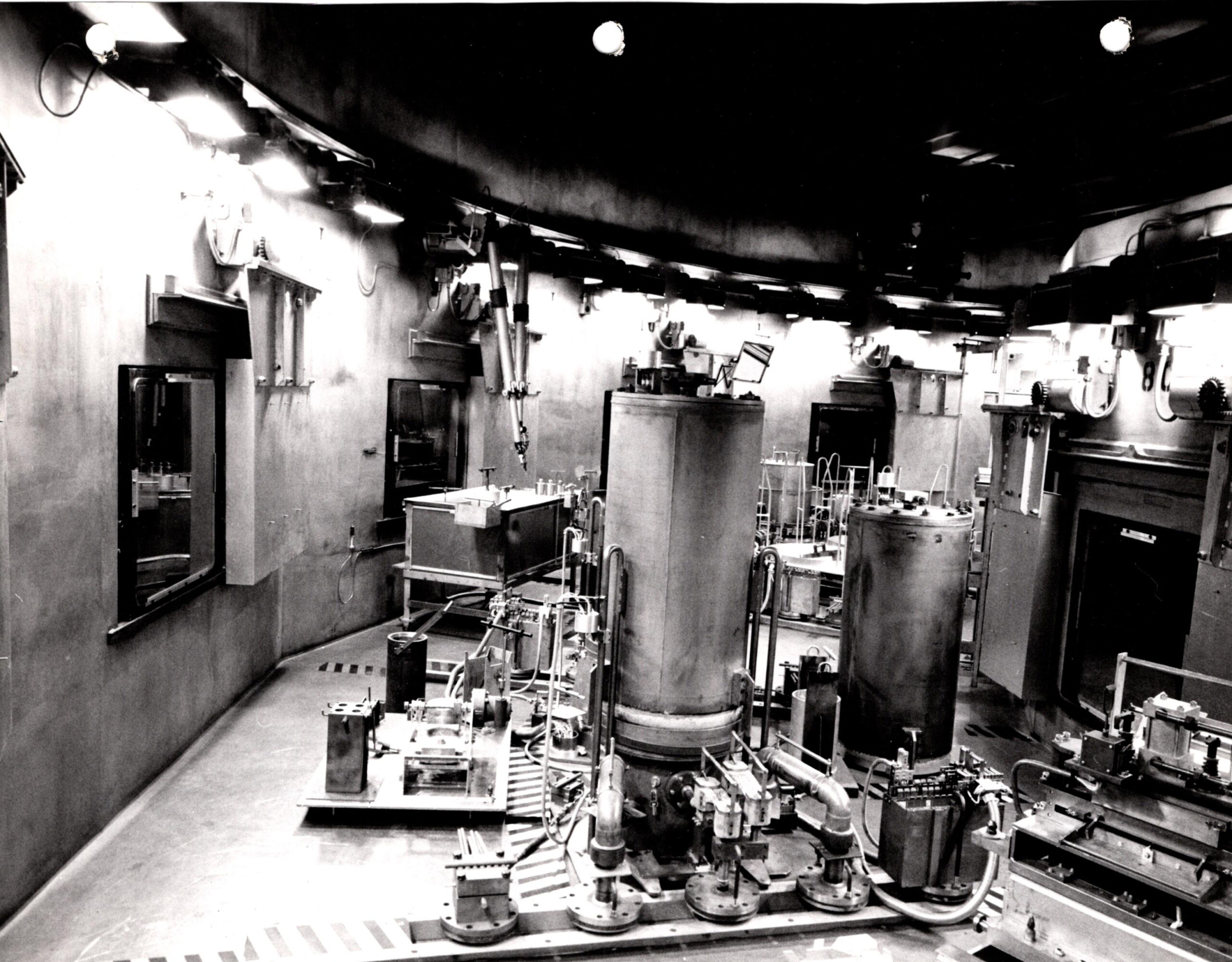

This high pressure 6-foot thick Cryogenic Vacuum Chamber Door has two layers of pneumatic pressure seals and was designed by Door-Man Manufacturing for NASA's Space Power Facility.

This high pressure 6-foot thick Cryogenic Vacuum Chamber Door has two layers of pneumatic pressure seals and was designed by Door-Man Manufacturing for NASA's Space Power Facility.

This high pressure 6-foot thick Cryogenic Vacuum Chamber Door has two layers of pneumatic pressure seals and was designed by Door-Man Manufacturing for NASA's Space Power Facility.

Designing the Control Standard

The original Electric Automatic Control Panel by Door-Man Manufacturing. Custom designed electric eyes and amplifiers plus Door-Man's LD-863 loop detectors and reversing edge controls became the standard entrance door control at automotive facilities in North America.

The original Electric Automatic Control Panel by Door-Man Manufacturing. Custom designed electric eyes and amplifiers plus Door-Man's LD-863 loop detectors and reversing edge controls became the standard entrance door control at automotive facilities in North America.

The original Electric Automatic Control Panel by Door-Man Manufacturing. Custom designed electric eyes and amplifiers plus Door-Man's LD-863 loop detectors and reversing edge controls became the standard entrance door control at automotive facilities in North America.

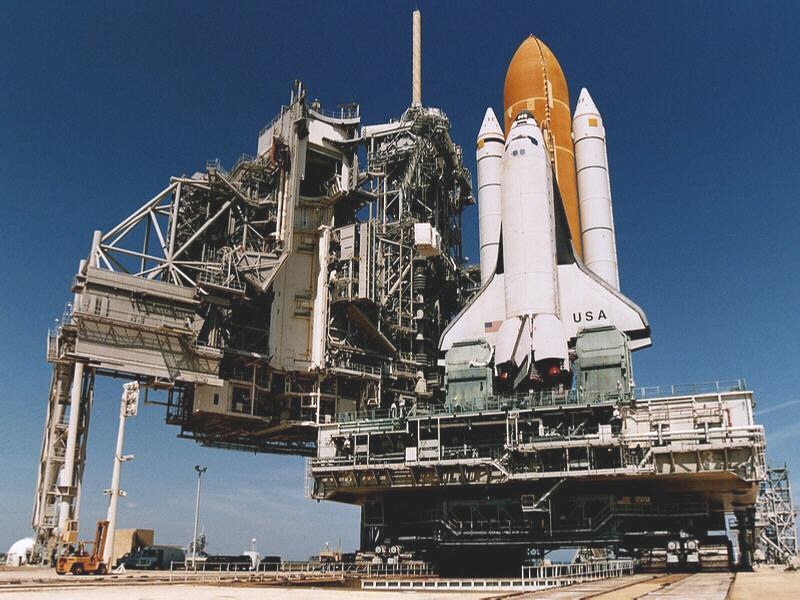

NASA's Trusted Source for Flight Success

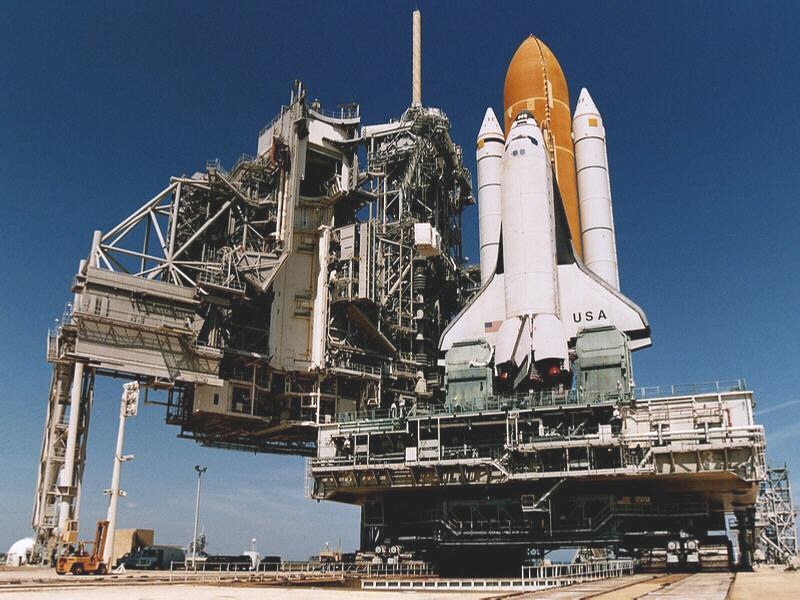

Beginning in 1978, Door-Man Manufacturing was awarded the design, furnishing, and installation of 6 projects on the Space Shuttle Launch Pad 39A Complex. On the exterior shell we provided the Monorail Transfer Doors and the main payload changeout room (PCR) 26' x 63' Folding Doors. Interior to the PCR were Vertical Lift and Swinging clean room doors and 10 levels of telescoping pneumatically operated titanium plank Platform Assemblies.

Beginning in 1978, Door-Man Manufacturing was awarded the design, furnishing, and installation of 6 projects on the Space Shuttle Launch Pad 39A Complex. On the exterior shell we provided the Monorail Transfer Doors and the main payload changeout room (PCR) 26' x 63' Folding Doors. Interior to the PCR were Vertical Lift and Swinging clean room doors and 10 levels of telescoping pneumatically operated titanium plank Platform Assemblies.

Beginning in 1978, Door-Man Manufacturing was awarded the design, furnishing, and installation of 6 projects on the Space Shuttle Launch Pad 39A Complex. On the exterior shell we provided the Monorail Transfer Doors and the main payload changeout room (PCR) 26' x 63' Folding Doors. Interior to the PCR were Vertical Lift and Swinging clean room doors and 10 levels of telescoping pneumatically operated titanium plank Platform Assemblies.

The Future of Transportation

Transpo72 at Washington Dulles International Airport showcased the international effort to design transportation for the future. Door-Man Manufacturing supplied the Ford Motor Company ACT Transportation Car Door Operators, Air Conditioning Systems, and designed the Track Diverter Systems for the Bendix-Dashaveyor automated guideway transit system which was installed and operational at the Toronto Zoo for many years.

Transpo72 at Washington Dulles International Airport showcased the international effort to design transportation for the future. Door-Man Manufacturing supplied the Ford Motor Company ACT Transportation Car Door Operators, Air Conditioning Systems, and designed the Track Diverter Systems for the Bendix-Dashaveyor automated guideway transit system which was installed and operational at the Toronto Zoo for many years.

Transpo72 at Washington Dulles International Airport showcased the international effort to design transportation for the future. Door-Man Manufacturing supplied the Ford Motor Company ACT Transportation Car Door Operators, Air Conditioning Systems, and designed the Track Diverter Systems for the Bendix-Dashaveyor automated guideway transit system which was installed and operational at the Toronto Zoo for many years.

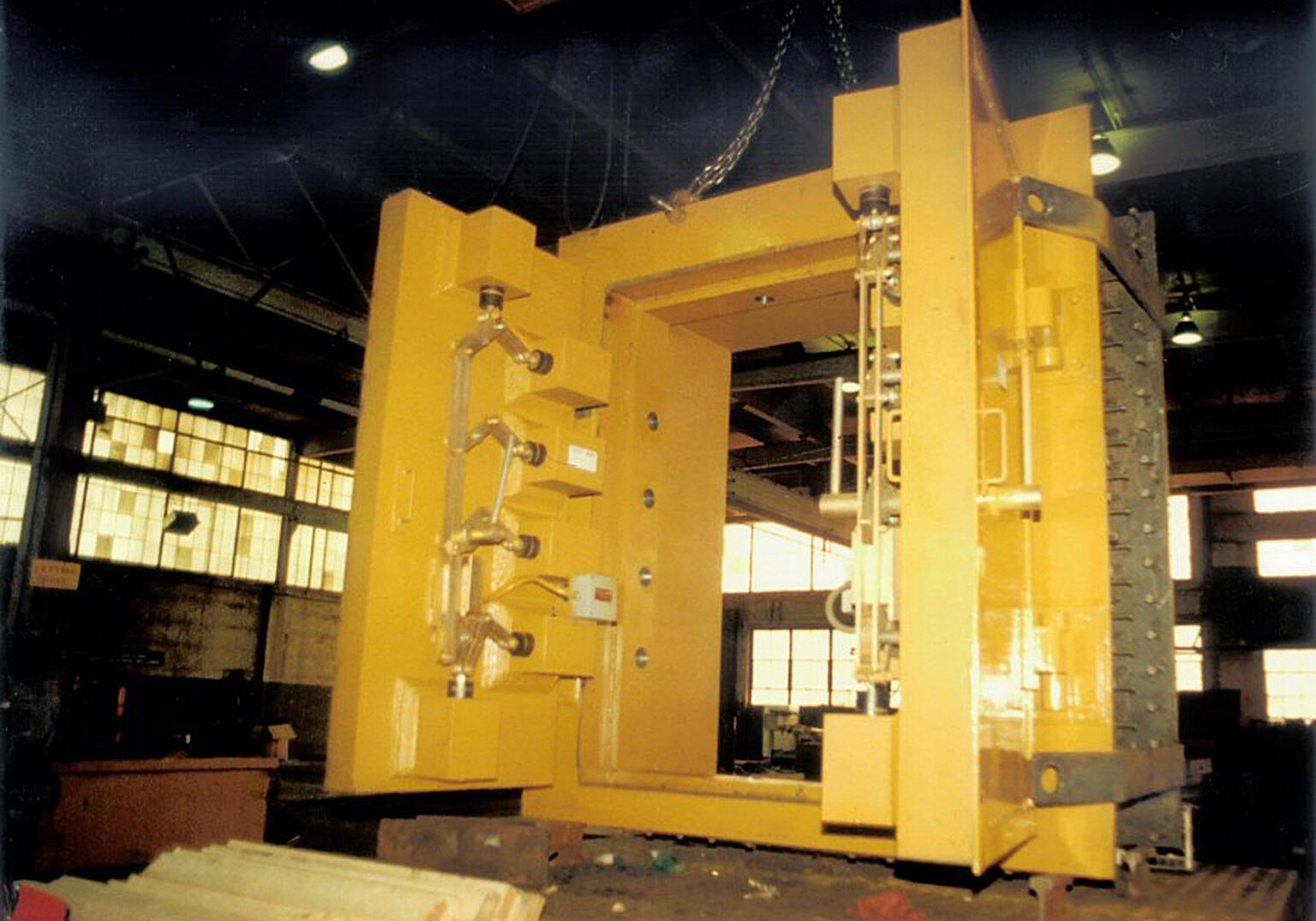

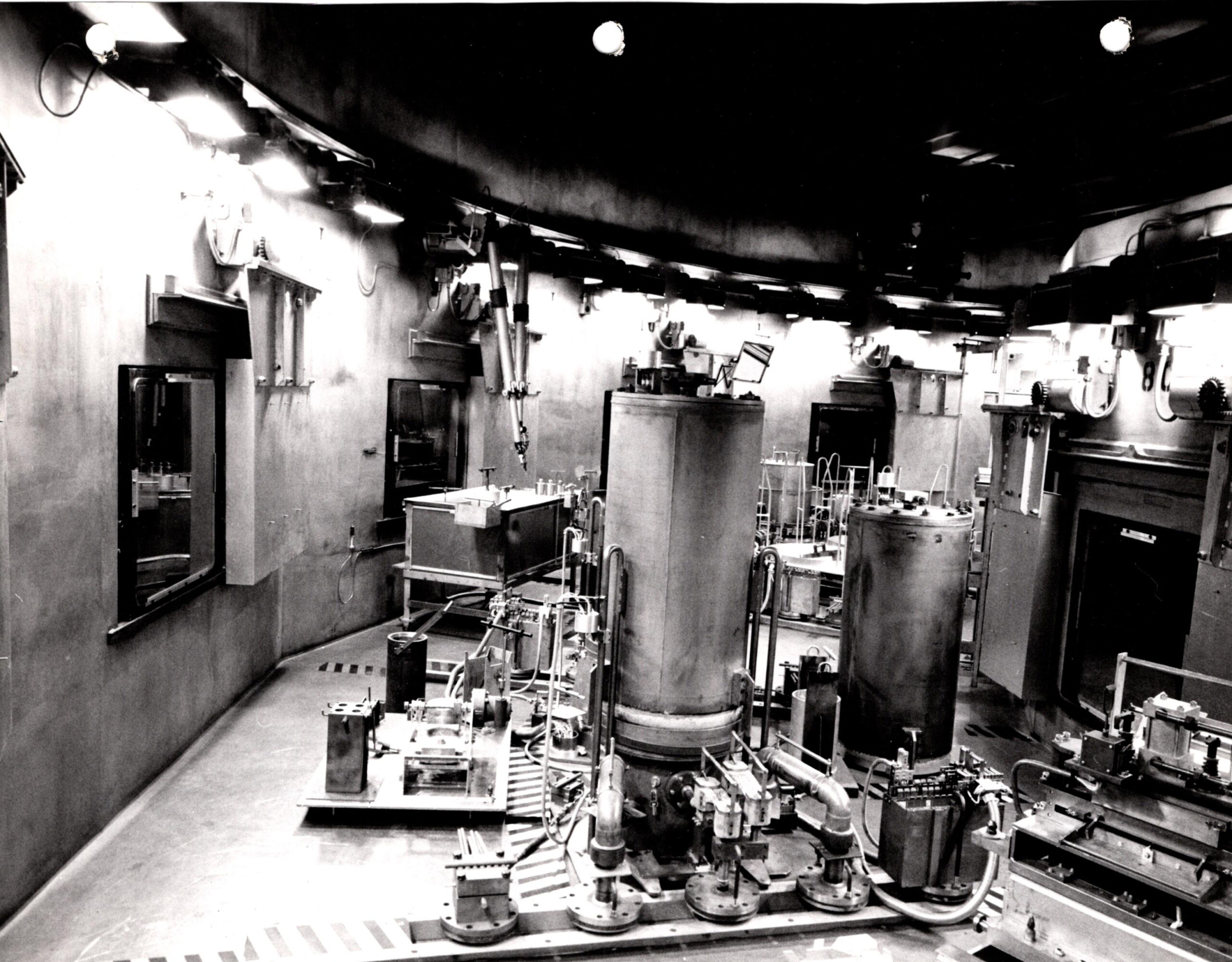

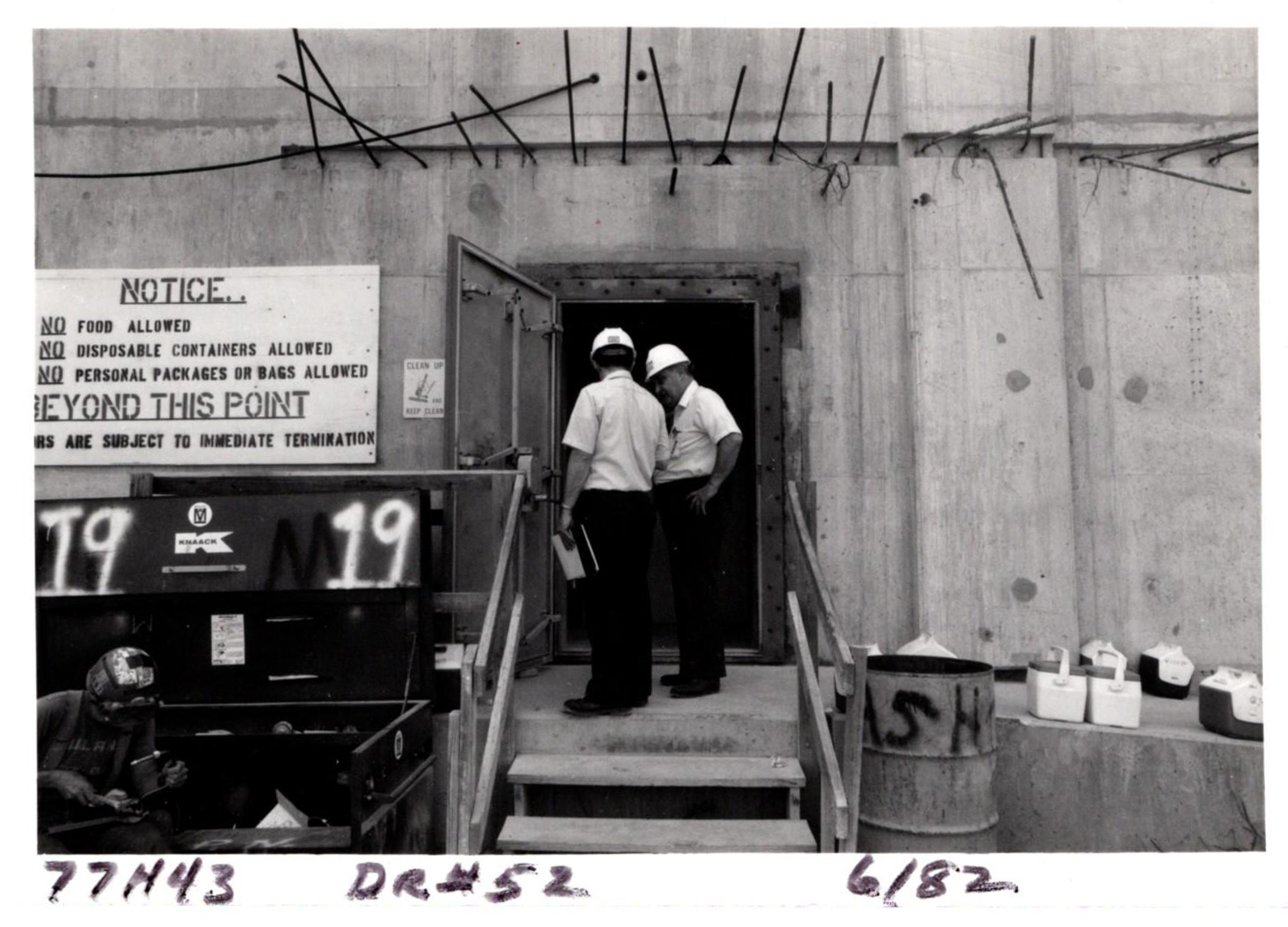

Specialty Doors for the Nuclear Industry

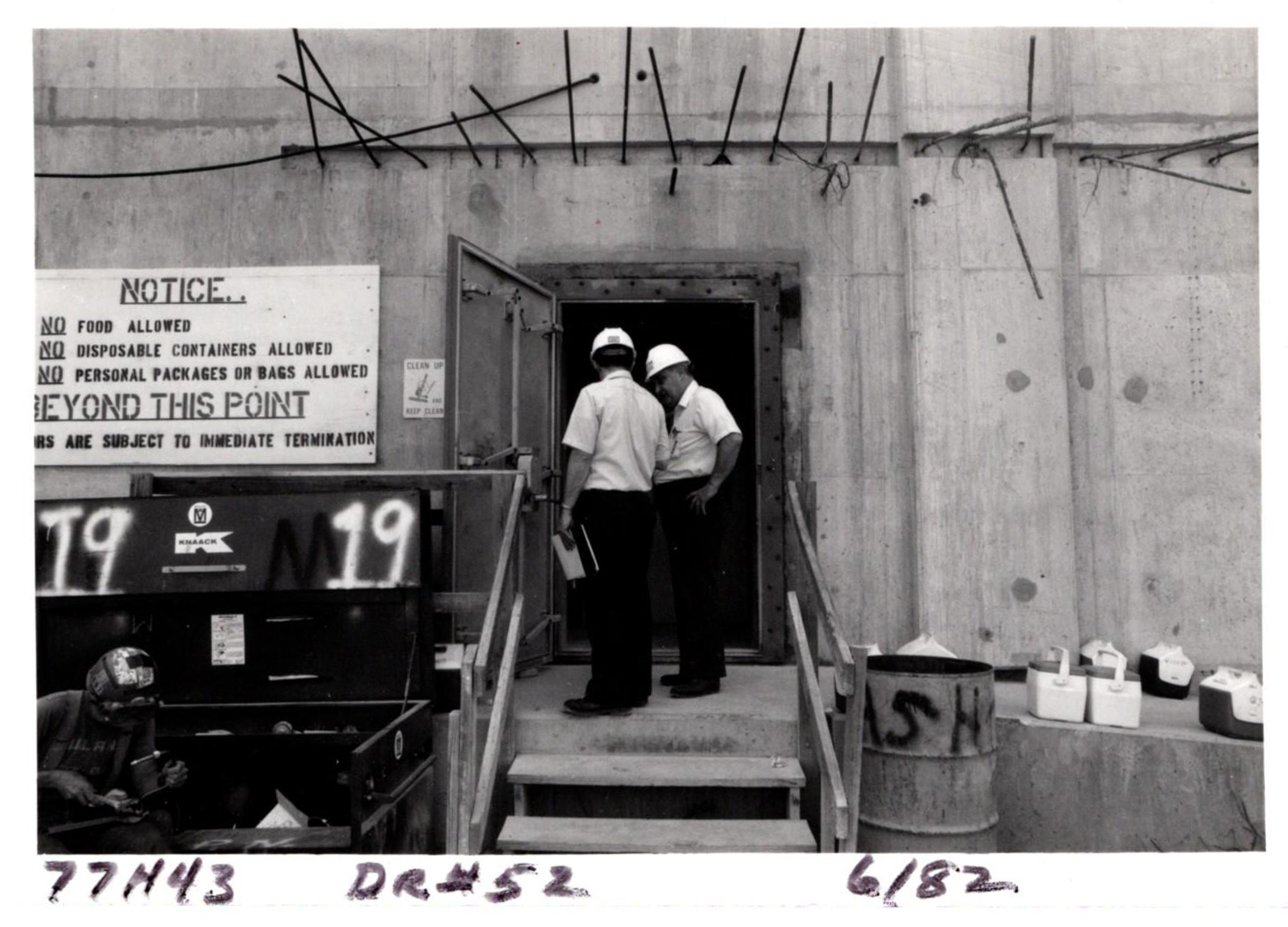

Throughout the 1970's and into the early 1980's, Door-Man Manufacturing supplied Radiation Shielding Doors, Blast Doors, Bullet Resistant Doors, and Watertight Bulkhead Doors. The door being inspected in the photograph is a patented Door-Man design for a 55 PSI Watertight Assembly which can be tested for water tightness in the field at any time with a hand pump and a pressure gauge.

Throughout the 1970's and into the early 1980's, Door-Man Manufacturing supplied Radiation Shielding Doors, Blast Doors, Bullet Resistant Doors, and Watertight Bulkhead Doors. The door being inspected in the photograph is a patented Door-Man design for a 55 PSI Watertight Assembly which can be tested for water tightness in the field at any time with a hand pump and a pressure gauge.

Throughout the 1970's and into the early 1980's, Door-Man Manufacturing supplied Radiation Shielding Doors, Blast Doors, Bullet Resistant Doors, and Watertight Bulkhead Doors. The door being inspected in the photograph is a patented Door-Man design for a 55 PSI Watertight Assembly which can be tested for water tightness in the field at any time with a hand pump and a pressure gauge.

Vertical Drop Doors at NASA

In the 1970's and 1980's, Door-Man supplied a total of four Vertical Drop 6-Leaf Aluminum Panel, 32' x 86.5' Doors at the Vehicle Assembly Center NASA Michoud Assembly. Doors in the open position allow various assemblies of rockets to be craned into position from the main bay to specialized work areas and chambers.

In the 1970's and 1980's, Door-Man supplied a total of four Vertical Drop 6-Leaf Aluminum Panel, 32' x 86.5' Doors at the Vehicle Assembly Center NASA Michoud Assembly. Doors in the open position allow various assemblies of rockets to be craned into position from the main bay to specialized work areas and chambers.

In the 1970's and 1980's, Door-Man supplied a total of four Vertical Drop 6-Leaf Aluminum Panel, 32' x 86.5' Doors at the Vehicle Assembly Center NASA Michoud Assembly. Doors in the open position allow various assemblies of rockets to be craned into position from the main bay to specialized work areas and chambers.

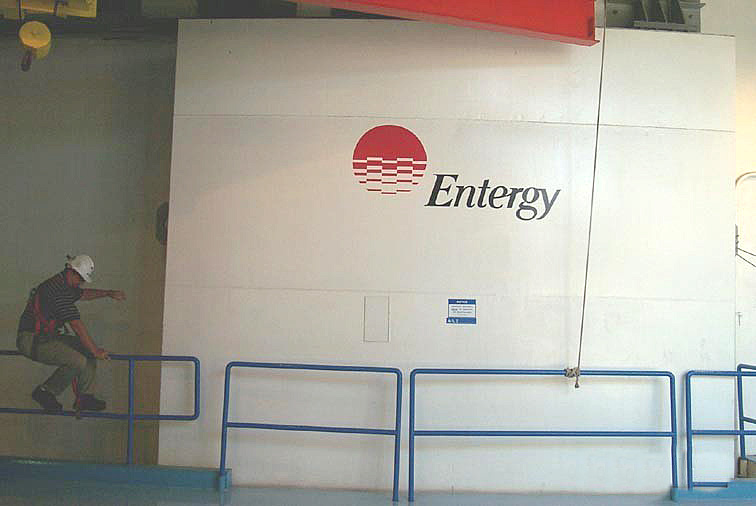

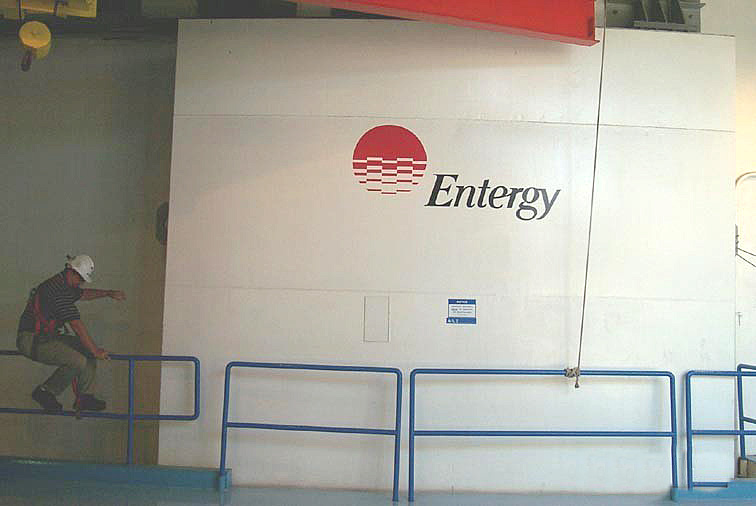

Safety in Nuclear Power

When nuclear power was gaining momentum as the future of efficient power, Door-Man Manufacturing supplied the industry with doors for every level of containment. This concrete shielding door at the Louisiana Power and Light Waterford III Nuclear Power Plant is curved to match the outer containment wall of the nuclear reactor.

When nuclear power was gaining momentum as the future of efficient power, Door-Man Manufacturing supplied the industry with doors for every level of containment. This concrete shielding door at the Louisiana Power and Light Waterford III Nuclear Power Plant is curved to match the outer containment wall of the nuclear reactor.

When nuclear power was gaining momentum as the future of efficient power, Door-Man Manufacturing supplied the industry with doors for every level of containment. This concrete shielding door at the Louisiana Power and Light Waterford III Nuclear Power Plant is curved to match the outer containment wall of the nuclear reactor.

Making a Blast Internationally

In the 1980's Door-Man was heavily involved in supplying Specialty Doors in Saudi Arabia. We supplied Blast Doors, Gas Tight Doors, Bullet Resistant Doors, and Specialty Doors and Frames to 18 long-range radar bases, 5 sector command centers, and the Royal Saudi Air Force Command and Control Center. Multiple Double Swinging 500 PSI Blast Rated Doors were supplied with specialty gas tight seals to stop the world's worst lethal war gases.

In the 1980's Door-Man was heavily involved in supplying Specialty Doors in Saudi Arabia. We supplied Blast Doors, Gas Tight Doors, Bullet Resistant Doors, and Specialty Doors and Frames to 18 long-range radar bases, 5 sector command centers, and the Royal Saudi Air Force Command and Control Center. Multiple Double Swinging 500 PSI Blast Rated Doors were supplied with specialty gas tight seals to stop the world's worst lethal war gases.

In the 1980's Door-Man was heavily involved in supplying Specialty Doors in Saudi Arabia. We supplied Blast Doors, Gas Tight Doors, Bullet Resistant Doors, and Specialty Doors and Frames to 18 long-range radar bases, 5 sector command centers, and the Royal Saudi Air Force Command and Control Center. Multiple Double Swinging 500 PSI Blast Rated Doors were supplied with specialty gas tight seals to stop the world's worst lethal war gases.

Acoustics in Production

R. V. Harty Co. began designing and manufacturing acoustical doors in the 1950's and Door-Man Manufacturing continued with its first STC 60 acoustical test at Riverbank Laboratory in 1972. When noise control and hearing protection became a focus in manufacturing in the 1980's, Door-Man was well prepared. The doors shown are Acoustic Vertical Lift in a STC 51 Dyno Cell application.

R. V. Harty Co. began designing and manufacturing acoustical doors in the 1950's and Door-Man Manufacturing continued with its first STC 60 acoustical test at Riverbank Laboratory in 1972. When noise control and hearing protection became a focus in manufacturing in the 1980's, Door-Man was well prepared. The doors shown are Acoustic Vertical Lift in a STC 51 Dyno Cell application.

R. V. Harty Co. began designing and manufacturing acoustical doors in the 1950's and Door-Man Manufacturing continued with its first STC 60 acoustical test at Riverbank Laboratory in 1972. When noise control and hearing protection became a focus in manufacturing in the 1980's, Door-Man was well prepared. The doors shown are Acoustic Vertical Lift in a STC 51 Dyno Cell application.

Controlling the Docks

In the early 1990's working with the American automotive industry and loading dock equipment manufacturers, Door-Man Manufacturing invented the full combination dock door control panel. These panels can include all the electrical components as required to control and interconnection operation of the door, dock leveler, trailer restraint, truck leveler, and truck shelter in a singlepanel with power disconnect for both safety and operational commonality at the loading dock.

In the early 1990's working with the American automotive industry and loading dock equipment manufacturers, Door-Man Manufacturing invented the full combination dock door control panel. These panels can include all the electrical components as required to control and interconnection operation of the door, dock leveler, trailer restraint, truck leveler, and truck shelter in a singlepanel with power disconnect for both safety and operational commonality at the loading dock.

In the early 1990's working with the American automotive industry and loading dock equipment manufacturers, Door-Man Manufacturing invented the full combination dock door control panel. These panels can include all the electrical components as required to control and interconnection operation of the door, dock leveler, trailer restraint, truck leveler, and truck shelter in a singlepanel with power disconnect for both safety and operational commonality at the loading dock.

Dominating the Competition

In 1998, the Dominator vertical lifting door was introduced, combining high strength light weight fiberglass, with the reliability of a counterweighted vertical lifting door. Options include high speed, insulation values up to R21, and insulated nonmetal window assemblies.

In 1998, the Dominator vertical lifting door was introduced, combining high strength light weight fiberglass, with the reliability of a counterweighted vertical lifting door. Options include high speed, insulation values up to R21, and insulated nonmetal window assemblies.

In 1998, the Dominator vertical lifting door was introduced, combining high strength light weight fiberglass, with the reliability of a counterweighted vertical lifting door. Options include high speed, insulation values up to R21, and insulated nonmetal window assemblies.

Architectural Innovation

In 1997, Door-Man Manufacturing designed and installed the stainless steel slide door on the front of the Armani Exchange at their flagship store on 5th Avenue in Manhattan, NYC. The door does not roll on the ground or hang from the top but is suspended and slides horizontally with a hidden operator.

In 1997, Door-Man Manufacturing designed and installed the stainless steel slide door on the front of the Armani Exchange at their flagship store on 5th Avenue in Manhattan, NYC. The door does not roll on the ground or hang from the top but is suspended and slides horizontally with a hidden operator.

In 1997, Door-Man Manufacturing designed and installed the stainless steel slide door on the front of the Armani Exchange at their flagship store on 5th Avenue in Manhattan, NYC. The door does not roll on the ground or hang from the top but is suspended and slides horizontally with a hidden operator.

Keeping the End Product Clean

Door-Man Manufacturing provided multiple movable truck shelters to minimize external contamination in automotive operations. The shelters allow a truck to enter the building and close the external building door before retracting the shelter for access to the truck. The powered operating system was embedded into the floor to allow for cross traffic and side unloading.

Door-Man Manufacturing provided multiple movable truck shelters to minimize external contamination in automotive operations. The shelters allow a truck to enter the building and close the external building door before retracting the shelter for access to the truck. The powered operating system was embedded into the floor to allow for cross traffic and side unloading.

Door-Man Manufacturing provided multiple movable truck shelters to minimize external contamination in automotive operations. The shelters allow a truck to enter the building and close the external building door before retracting the shelter for access to the truck. The powered operating system was embedded into the floor to allow for cross traffic and side unloading.

Improving an Age-Old Design

Taking a great product and making it better, Door-Man Manufacturing patented a Full Knock Out and easily resettable Dominator Vertical Lift Door. In addition, a bottom mounted operator mounted within the tower assembly allowed for the ease of maintenance and to protect it from damage.

Taking a great product and making it better, Door-Man Manufacturing patented a Full Knock Out and easily resettable Dominator Vertical Lift Door. In addition, a bottom mounted operator mounted within the tower assembly allowed for the ease of maintenance and to protect it from damage.

Taking a great product and making it better, Door-Man Manufacturing patented a Full Knock Out and easily resettable Dominator Vertical Lift Door. In addition, a bottom mounted operator mounted within the tower assembly allowed for the ease of maintenance and to protect it from damage.

Broadening Our Horizons

For the Canadian National Defense in Shearwater, Nova Scotia, we supplied multiple helicopter Hangar Doors from 30' wide to 80' wide. These doors were designed to withstand and operate under post disaster conditions and for wind speeds up to 270 kilometers.

For the Canadian National Defense in Shearwater, Nova Scotia, we supplied multiple helicopter Hangar Doors from 30' wide to 80' wide. These doors were designed to withstand and operate under post disaster conditions and for wind speeds up to 270 kilometers.

For the Canadian National Defense in Shearwater, Nova Scotia, we supplied multiple helicopter Hangar Doors from 30' wide to 80' wide. These doors were designed to withstand and operate under post disaster conditions and for wind speeds up to 270 kilometers.

Promoting Safety in the Workplace

Door-Man Manufacturing recognized the need for traffic caution systems and alerts to address the daily hazards of people working with and around industrial vehicles and introduced the ICS. The patent for this Intersection Caution System was granted in 2005.

Door-Man Manufacturing recognized the need for traffic caution systems and alerts to address the daily hazards of people working with and around industrial vehicles and introduced the ICS. The patent for this Intersection Caution System was granted in 2005.

Door-Man Manufacturing recognized the need for traffic caution systems and alerts to address the daily hazards of people working with and around industrial vehicles and introduced the ICS. The patent for this Intersection Caution System was granted in 2005.

Production and Welding Applications

As automation in manufacturing increased, our expertise allowed us to offer electric and pneumatic high cycle doors for production applications, including these Light-Tight Bi-Parting Pneumatic Doors for a laser welding booth for an automotive manufacturing plant in Mexico.

As automation in manufacturing increased, our expertise allowed us to offer electric and pneumatic high cycle doors for production applications, including these Light-Tight Bi-Parting Pneumatic Doors for a laser welding booth for an automotive manufacturing plant in Mexico.

As automation in manufacturing increased, our expertise allowed us to offer electric and pneumatic high cycle doors for production applications, including these Light-Tight Bi-Parting Pneumatic Doors for a laser welding booth for an automotive manufacturing plant in Mexico.

Stopping Sound at 163dB

Combining our experience with NASA and Acoustic Doors, we were able to design and manufacture this Swinging, Acoustic Concrete Filled Door, 14' x 18', weighing 166,000 lbs. located in the Reverberant Test Facility at the NASA Neil A. Armstrong Facility. The door system is acoustically designed for an overall sound pressure level of 163dB.

Combining our experience with NASA and Acoustic Doors, we were able to design and manufacture this Swinging, Acoustic Concrete Filled Door, 14' x 18', weighing 166,000 lbs. located in the Reverberant Test Facility at the NASA Neil A. Armstrong Facility. The door system is acoustically designed for an overall sound pressure level of 163dB.

Combining our experience with NASA and Acoustic Doors, we were able to design and manufacture this Swinging, Acoustic Concrete Filled Door, 14' x 18', weighing 166,000 lbs. located in the Reverberant Test Facility at the NASA Neil A. Armstrong Facility. The door system is acoustically designed for an overall sound pressure level of 163dB.

SHURE STAR Continues the Legacy

In 2011, SHURE STAR acquired Door-Man, maintaining continuity of staff and improving upon engineering capabilities and processes with 3D modeling and analysis tools. Door shown is a Vertical Lift Dominator 3-Leaf Door, exterior mount with removable windows and insertable screens for ventilation.

In 2011, SHURE STAR acquired Door-Man, maintaining continuity of staff and improving upon engineering capabilities and processes with 3D modeling and analysis tools. Door shown is a Vertical Lift Dominator 3-Leaf Door, exterior mount with removable windows and insertable screens for ventilation.

In 2011, SHURE STAR acquired Door-Man, maintaining continuity of staff and improving upon engineering capabilities and processes with 3D modeling and analysis tools. Door shown is a Vertical Lift Dominator 3-Leaf Door, exterior mount with removable windows and insertable screens for ventilation.

Controls For Hazardous Environments

As an Underwriters Laboratories U.L. 508A designer and manufacturer, SHURE STAR provides NEMA type 7/9 Explosion Proof Controls not just for SHURE STAR doors, but for many other door, loading dock, and other equipment manufacturers when their equipment needs to operate in a hazardous environment.

As an Underwriters Laboratories U.L. 508A designer and manufacturer, SHURE STAR provides NEMA type 7/9 Explosion Proof Controls not just for SHURE STAR doors, but for many other door, loading dock, and other equipment manufacturers when their equipment needs to operate in a hazardous environment.

As an Underwriters Laboratories U.L. 508A designer and manufacturer, SHURE STAR provides NEMA type 7/9 Explosion Proof Controls not just for SHURE STAR doors, but for many other door, loading dock, and other equipment manufacturers when their equipment needs to operate in a hazardous environment.

High Production with SHURE STAR

These high production stamping press doors for a major automotive manufacturing plant were supplied to multiple facilities. Integral design with the acoustic booths allowed for the maximum clearance and vision in an STC 45 construction.

These high production stamping press doors for a major automotive manufacturing plant were supplied to multiple facilities. Integral design with the acoustic booths allowed for the maximum clearance and vision in an STC 45 construction.

These high production stamping press doors for a major automotive manufacturing plant were supplied to multiple facilities. Integral design with the acoustic booths allowed for the maximum clearance and vision in an STC 45 construction.

When One Door Is Not Enough

SHURE STAR can combine door types to provide the right product for application. This bottom Sliding 26' x 31' door is guided above with a track in the upper Canopy door. The upper Canopy door, which is 84' x 12', opens to its full width to allow a crane to exit the building, transporting large shipping containers through the Sliding door below.

SHURE STAR can combine door types to provide the right product for application. This bottom Sliding 26' x 31' door is guided above with a track in the upper Canopy door. The upper Canopy door, which is 84' x 12', opens to its full width to allow a crane to exit the building, transporting large shipping containers through the Sliding door below.

SHURE STAR can combine door types to provide the right product for application. This bottom Sliding 26' x 31' door is guided above with a track in the upper Canopy door. The upper Canopy door, which is 84' x 12', opens to its full width to allow a crane to exit the building, transporting large shipping containers through the Sliding door below.

Weapon Storage Across the Globe

SHURE STAR has expanded it’s product offerings and market to Munition Storage facilities across the globe. These double swinging blast doors with internal pedestrian doors were designed and built specifically for these, 7 bars (101.5 PSI) ECMs. This 26’ wide x 13’ tall door is one of 32 supplied on this project.

SHURE STAR has expanded it’s product offerings and market to Munition Storage facilities across the globe. These double swinging blast doors with internal pedestrian doors were designed and built specifically for these, 7 bars (101.5 PSI) ECMs. This 26’ wide x 13’ tall door is one of 32 supplied on this project.

SHURE STAR has expanded it’s product offerings and market to Munition Storage facilities across the globe. These double swinging blast doors with internal pedestrian doors were designed and built specifically for these, 7 bars (101.5 PSI) ECMs. This 26’ wide x 13’ tall door is one of 32 supplied on this project.

Blast Resistant Design

With blast pressures designed and manufactured to withstand over 15,000 PSI, SHURE STAR's military and private sector Blast Doors can meet almost any requirement. Designed and produced as Swinging, Sliding, Vertical Lifting, Folding, and other special configurations, we can engineer your product with 3-D design, backed up with Licensed PE analysis when required. These doors are available with fragmentation resistant design, specialty hardware and power operation, for the harshest environments.

With blast pressures designed and manufactured to withstand over 15,000 PSI, SHURE STAR's military and private sector Blast Doors can meet almost any requirement. Designed and produced as Swinging, Sliding, Vertical Lifting, Folding, and other special configurations, we can engineer your product with 3-D design, backed up with Licensed PE analysis when required. These doors are available with fragmentation resistant design, specialty hardware and power operation, for the harshest environments.

With blast pressures designed and manufactured to withstand over 15,000 PSI, SHURE STAR's military and private sector Blast Doors can meet almost any requirement. Designed and produced as Swinging, Sliding, Vertical Lifting, Folding, and other special configurations, we can engineer your product with 3-D design, backed up with Licensed PE analysis when required. These doors are available with fragmentation resistant design, specialty hardware and power operation, for the harshest environments.

Key dates in our history:

• 1918 - R. V. Harty Co. begins designing, manufacturing and installing doors

• 1949 - Inception of Door-Man Manufacturing

• 1963 - Door-Man Manufacturing acquires R. V. Harty Co.

• 2011 - SHURE STAR acquires Door-Man

Let SHURE STAR Make Your Next Project A Success

Our partnership with our customers is centered around constantly improving our products and service through:

• In-house design and engineering using Solidworks 3-D design, analysis and product data management software

• 3rd party structural and/or blast design analysis from highly qualified and experienced licensed professional engineers

• In-house machining that allows us to design and build custom hardware required for unique designs and applications

• Maintaining material traceability for all structural steel fabrications

• Welding performed to AWS standards by AWS certified weld operators

SHURE STAR Has It All - Doors, Controls, Safety Systems, and More!

From specialty controls and safety systems, to experienced and expert resources that help guide you to the perfect product for your application, look to SHURE STAR.

Doors

View our gallery of projects organized by configuration type, including variations of Vertical Lift, Swing, Slide, and Fold Doors.

Visit our gallery of successful projects organized by application, showcasing the range of available options.

We Offer Complete Design And Manufacturing For All Your Door Needs.

At SHURE STAR, we design and manufacture specialty doors specifically for your application. From the examples shown here on our website, to original concepts designed specifically to your needs, SHURE STAR remains unmatched in our custom design and fabrication for unusual applications and special requirements.

Design Resources

SHURE STAR specializes in products designed to perform, including blast and pressure resistant, acoustic, environmental, high cycle, high speed, architectural, and more. Using our tools, insight and decades of experience, SHURE STAR will help guide you to the right type of product and design it specifically for your unique circumstances.

Replacement Parts

Need a replacement part for a SHURE STAR, Door-Man, or other door? SHURE STAR has you covered. In addition to parts for our doors, we can reverse engineer or re-design and manufacture obsolete, hard to find, and custom parts for doors made by others. Contact us today, we are ready to help!

SHURE STAR is dedicated to providing the very best customer service possible. Any information provided to us is held in the strictest of confidence. NDAs and information security including FOUO and UNCI document control are common practice for us. We are in the process preparing for upcoming DoD Cybersecurity Maturity Model Certification requirements. You can trust SHURE STAR to take your privacy and the security of your information seriously.

Use of our website constitutes agreement with these terms and conditions. No part of this website shall be reproduced in whole or in part without approval from SHURE STAR. The information presented in this website is for demonstration purposes only, and may or may not apply to your specific project. SHURE STAR is not responsible for any promises or commitments not offered or intended to be offered.